What is Cermet?

The word cermet is a contraction of “ceramic” and “metal”. Cermet consists of a ceramic material (such as titanium carbide or titanium carbonitride) cemented with a metal binder. The ceramic provides the wear resistance, while the metal provides the toughness. This combination is more chemically inert than tungsten carbide and means that edge buildup and crater wear are much less likely compared to cemented carbide.

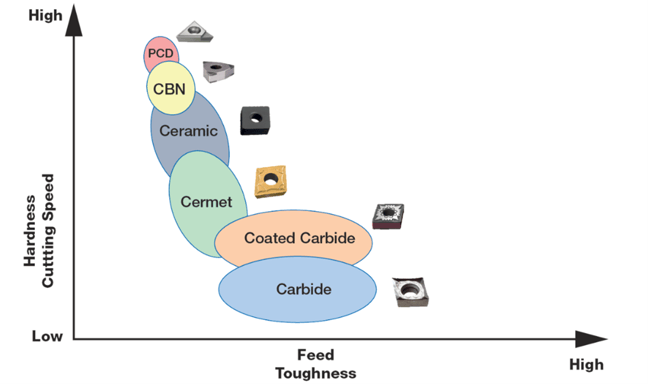

Looking at the chart below, it shows the comparison of cermet over coated carbide and carbide. Coated cermet is also available, which can extend the tools cutting life even further.

Cermet Advantages vs. Cemented Carbide

-

Improved tool life

-

Lower micro finish

-

Higher cutting speeds

-

High dimensional stability, able to achieve tight tolerances

-

Minimal edge buildup, even with MQL

-

Reduced crater and flank wear